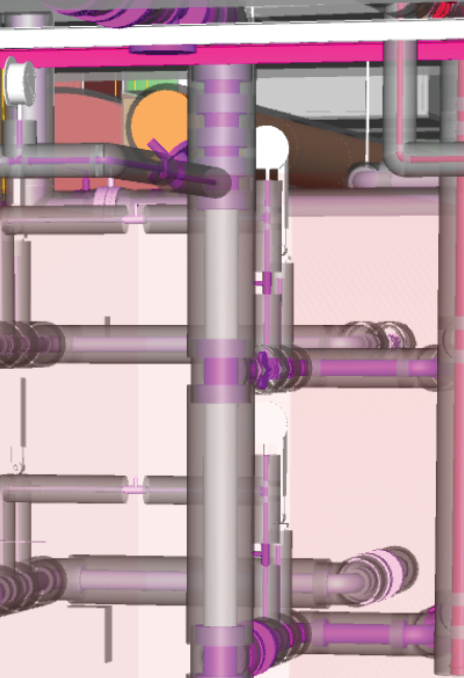

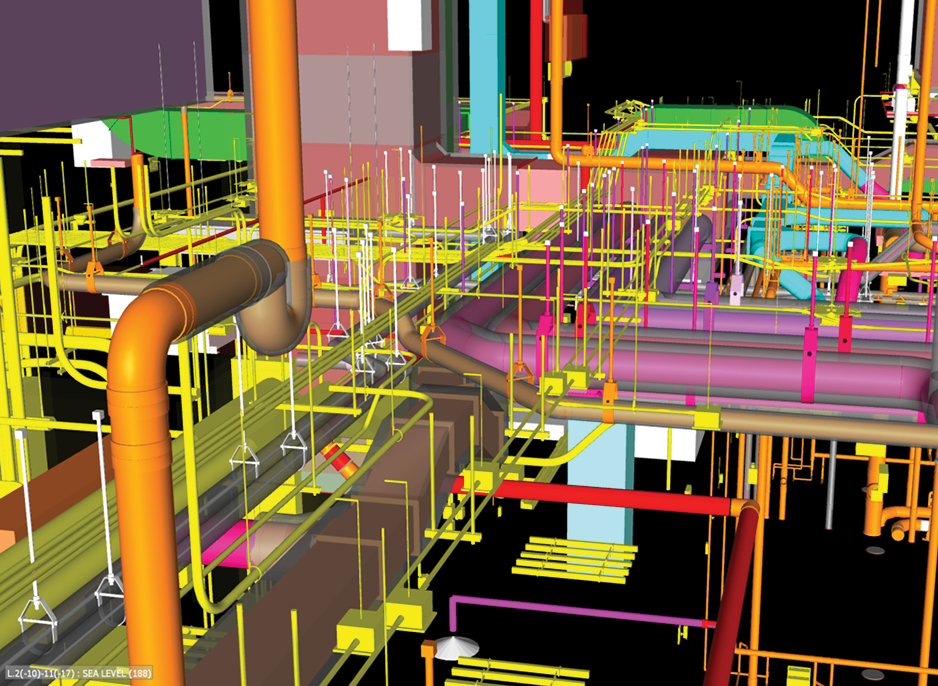

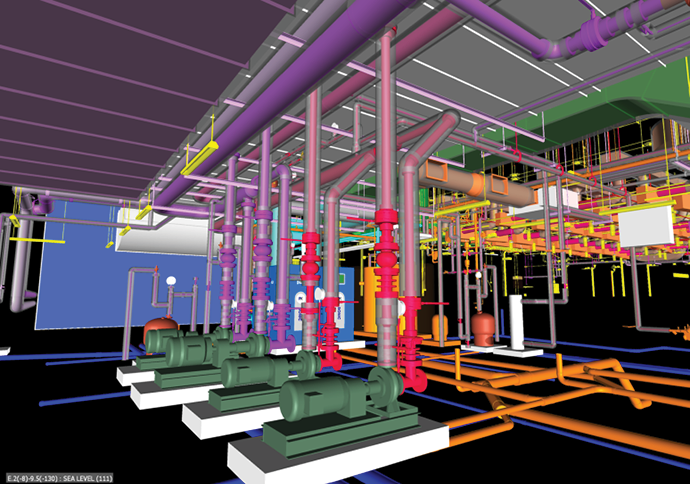

BIM

The Building Information Modeling (BIM) process revolutionizes how we conceive, design, construct, and manage buildings and infrastructure projects. By digitally representing the physical and functional characteristics of places, BIM enables us to work with stakeholders collaboratively on a project from its inception to its completion and beyond, fostering transparency, efficiency, and innovation throughout the entire lifecycle, before a shovel hits the ground. Through integrating various disciplines and data sources BIM streamlines workflows, enhances decision-making processes, reduces errors, and ultimately delivers higher quality, more sustainable built environments.

Comprehensive preconstruction planning and BIM have led to successful projects for our clients such as Archbold Hospital, HCA Hospital System, Florida State University, Florida A&M University, Tallahassee Community College, Valdosta State University, and other private and public commercial industries.

Prefabrication

The MillerWorks difference: prefabricating plumbing and mechanical systems in a controlled environment which offers advantages to your job quality such as:

– Safety

Working in a controlled environment instead of the job site reduces the risk of on-site injury and lost time incidents.

– Increased Productivity

Prefabricating components off-site allows production to continue even when the project would typically not have plumbers and mechanics on site, such as steel erection.

– Eliminates the Weather Factor

A climate-controlled environment from the discomfort of heat or cold allows workers to focus on quality without distractions.

– Improves Scheduling

Having components already assembled and ready for installation lead to less time in the areas which allows subsequent trade work to begin sooner.

– Reduces Waste

Instead of scrap pieces being thrown away or lost on-site, those materials can now be used in other assemblies, ultimately saving the project and client money.

– Quality Control

Assembly and pre-testing off-site allow a level of QC unachievable through traditional methods, decreasing testing and repair times in the field.